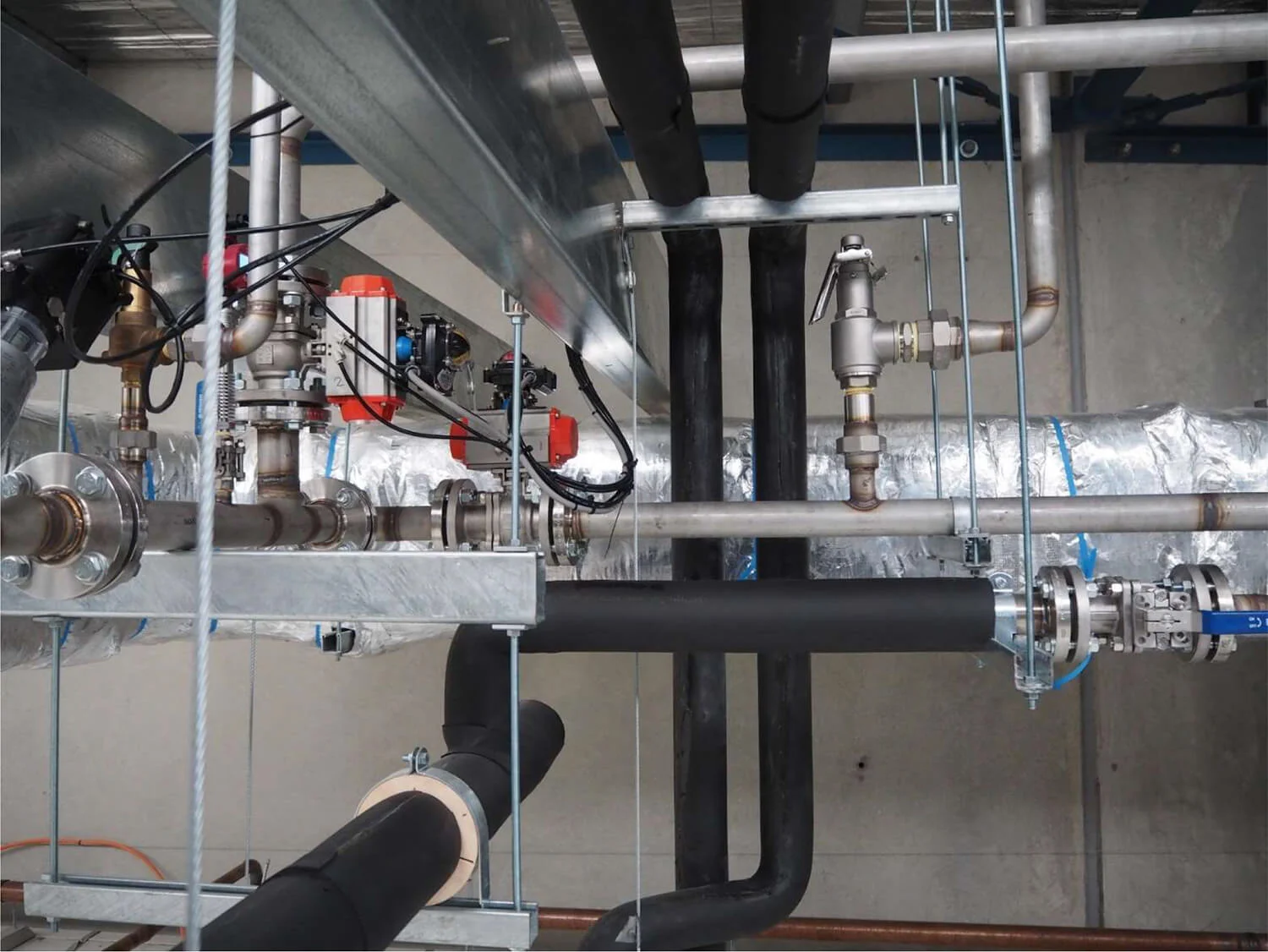

Extended shelf life system installation

FMA recently completed the design, manufacture and installation of

a large Extended Shelf Life (ESL) installation.

The machinery supplied:- 1000L FMA horizontal agitated kettle with

- 500L FMA horizontal agitated kettle (as above)

- Two FMA form fill seal packaging machines. The third unit was existing

- Four FMA Linear Water Chillers With refrigeration evaporators

- Six modular belt conveyors

- One FMA pressure cooking system with ribbon blender, direct steam injection and jacket heading

- Duel steam jackets

- Load cells

- Euro bin lifter

- Clean in place (CIP)

- Sanitary divesion valves automatically

- Positioned to the requirement of a specific operation

- Intergrated sanitary food pump

- Intergrated food emulsifer

- Touch screen HMI

- ESL (Extended Shelf Life) Cook Chill is a meal production system that employs rapid chilling of food cooked in, or transferred into, plastic packaging.

- Rapid product chilling is critical to extended shelf life, cook-chill and sous vide processes.

- All FMA systems are PLC controlled with data storage facilities, for quality and HACCAP control.

- FMA has over 25 years of experience in cook chill projects ranging in size from 500 to 30000 meals per day.

- FMA manufactures in Australia all of the components needed for a quality ESL Cook/Chill System, including Cook/Chill Tanks, Oscillating and Tumble Chillers as well as Kettles, Brat Pans and Transfer Systems.