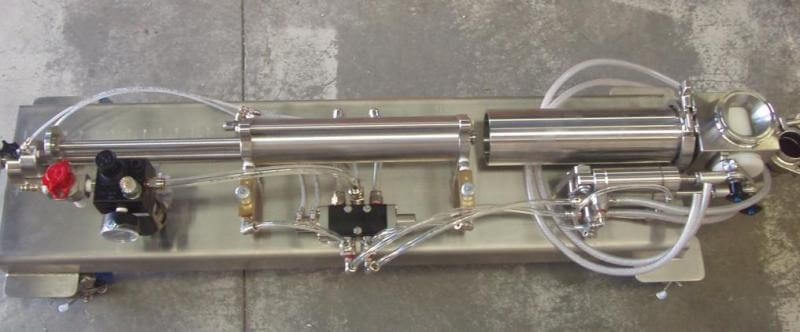

Delivers a broad range of fill volumes via a fast & simple screw adjustment from 30mL up to 15L Fill volume is accurate & consistent Tapered fill ports eliminate product (solids) damage Can operate at 10 to over 60 cycles-per-minute, to handle different product needs. Foot pedal activation, with single cycle or continuous setting and pneumatic flow control to regulate cycle speed Compact and mobile, for easy use, storage & cleaning No electric components, and can be washed down Available with 12.5mm to 150mm piston diameter and

For the production kitchen, desiring to significantly reduce packaging labor and material costs. The FMA vertical form-fill-seal is a simple, accurate and easy to operate machine which forms a flexible pouch from a roll of film, heat seals the lapped vertical edges, fills the pouch and then closes the pouch with a final horizontal heat seal. This versatile machine can produce pouches from 60mL to over 12 L. Readily accommodates dry products, wet products or a combination of wet and dry. Volumetric filling is

100L to 400L Electrical, steam , LPG or natural gas heated Fully agitated cooking surface Hydraulically tilting Exceptional results with a range of products from custards, soups, roux to fried rice, jams and curries Expert Customised Solutions, Concepts & Systems for the food industry.

Purees food to a consistency that is acceptable to the dieticians requirements Can be manufactured as a mobile in-line unit or can be fitted permanently to an agitated kettle Expert Customised Solutions, Concepts & Systems for the food industry.

- 1

- 2